ASTM F2896-23

(Specification)Standard Specification for Reinforced Polyethylene Composite Pipe For The Transport Of Oil And Gas And Hazardous Liquids

Standard Specification for Reinforced Polyethylene Composite Pipe For The Transport Of Oil And Gas And Hazardous Liquids

SCOPE

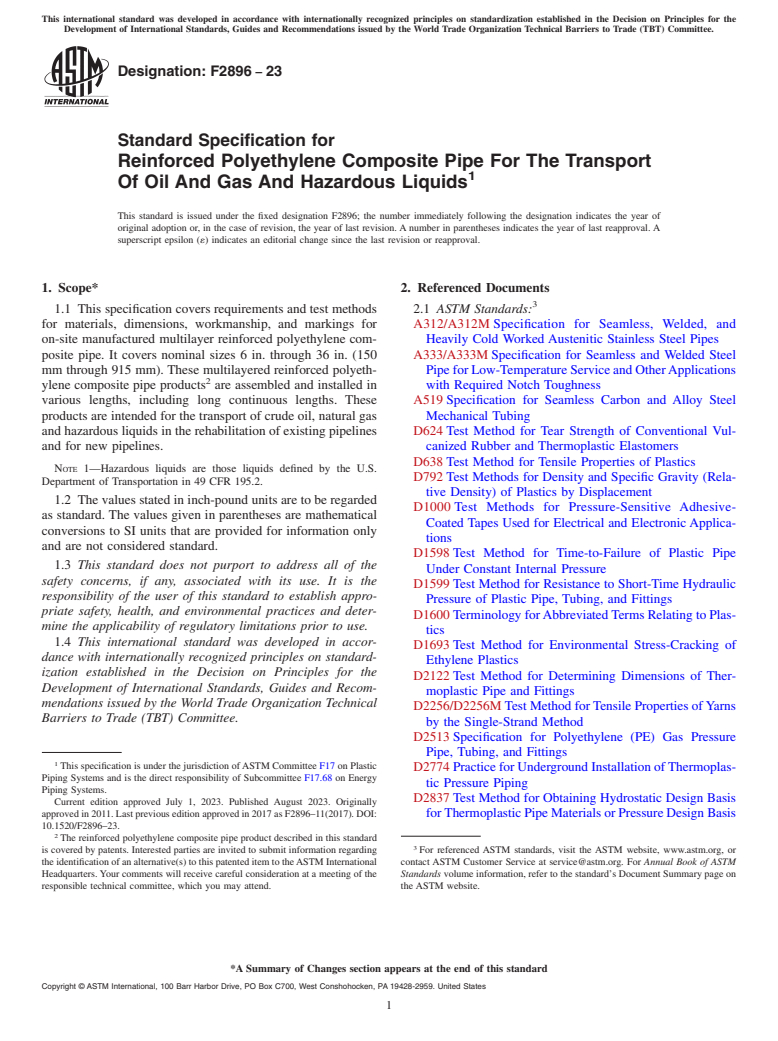

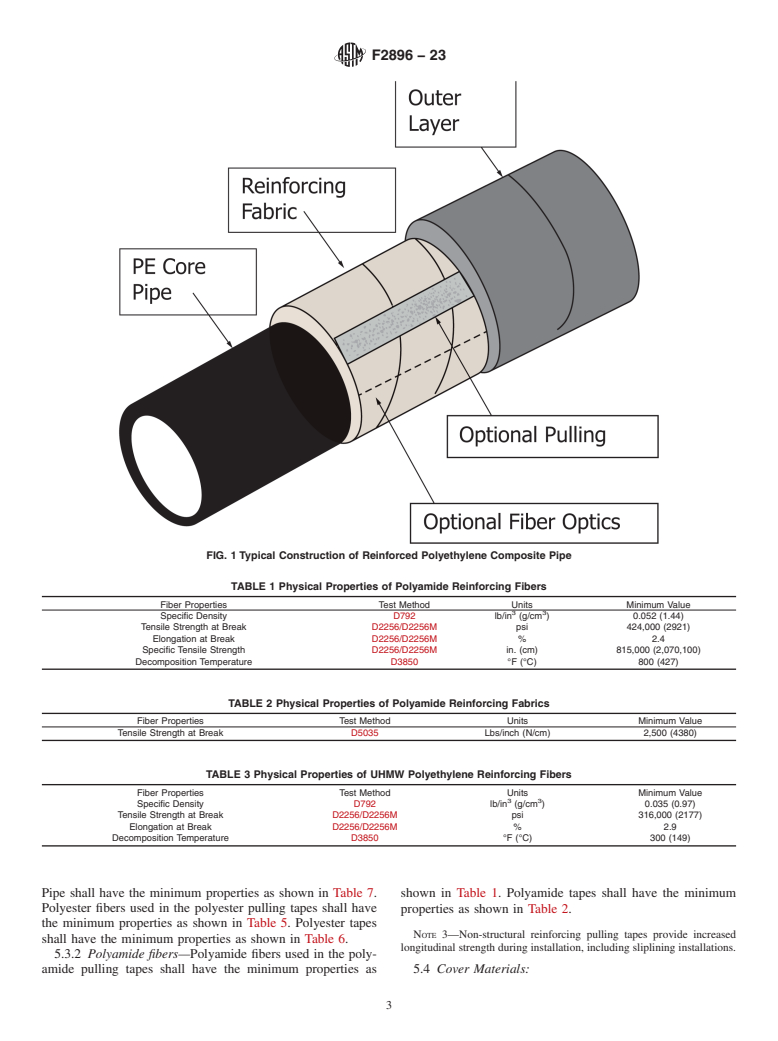

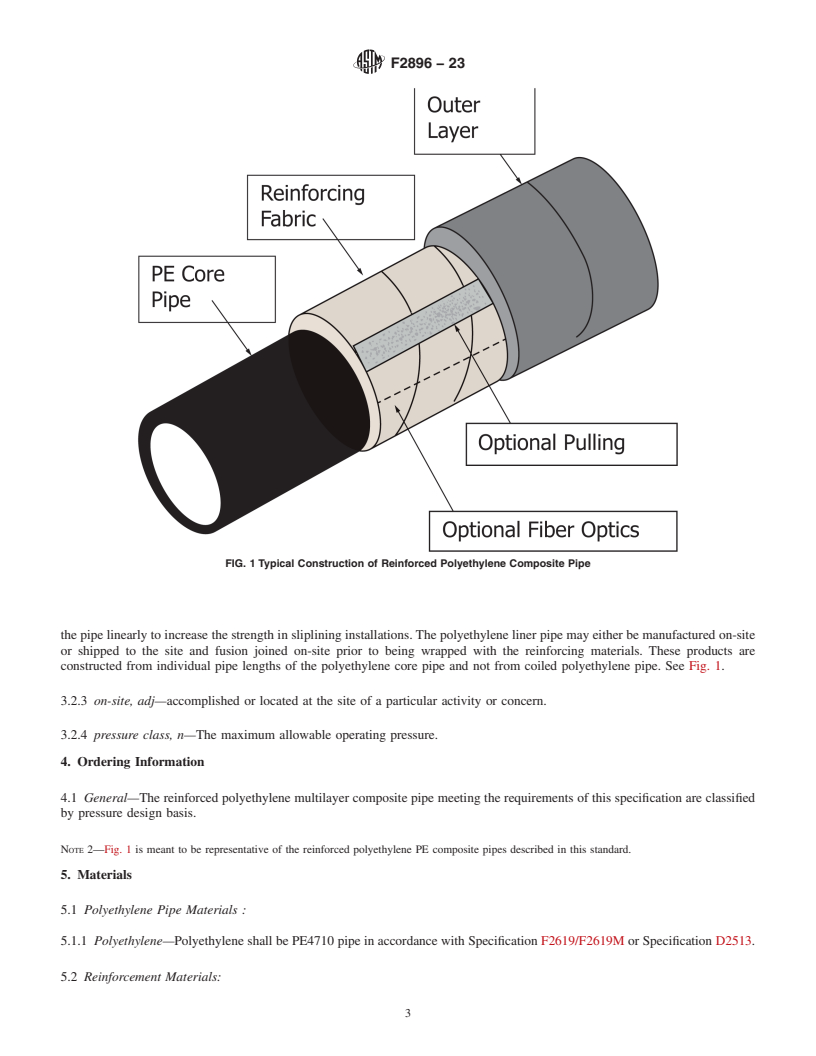

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, and markings for on-site manufactured multilayer reinforced polyethylene composite pipe. It covers nominal sizes 6 in. through 36 in. (150 mm through 915 mm). These multilayered reinforced polyethylene composite pipe products2 are assembled and installed in various lengths, including long continuous lengths. These products are intended for the transport of crude oil, natural gas and hazardous liquids in the rehabilitation of existing pipelines and for new pipelines.

Note 1: Hazardous liquids are those liquids defined by the U.S. Department of Transportation in 49 CFR 195.2.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2896 − 23

Standard Specification for

Reinforced Polyethylene Composite Pipe For The Transport

1

Of Oil And Gas And Hazardous Liquids

This standard is issued under the fixed designation F2896; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* 2. Referenced Documents

3

1.1 This specification covers requirements and test methods 2.1 ASTM Standards:

for materials, dimensions, workmanship, and markings for A312/A312M Specification for Seamless, Welded, and

on-site manufactured multilayer reinforced polyethylene com- Heavily Cold Worked Austenitic Stainless Steel Pipes

posite pipe. It covers nominal sizes 6 in. through 36 in. (150 A333/A333M Specification for Seamless and Welded Steel

mm through 915 mm). These multilayered reinforced polyeth- Pipe for Low-Temperature Service and Other Applications

2

ylene composite pipe products are assembled and installed in with Required Notch Toughness

various lengths, including long continuous lengths. These A519 Specification for Seamless Carbon and Alloy Steel

products are intended for the transport of crude oil, natural gas Mechanical Tubing

and hazardous liquids in the rehabilitation of existing pipelines D624 Test Method for Tear Strength of Conventional Vul-

and for new pipelines. canized Rubber and Thermoplastic Elastomers

D638 Test Method for Tensile Properties of Plastics

NOTE 1—Hazardous liquids are those liquids defined by the U.S.

D792 Test Methods for Density and Specific Gravity (Rela-

Department of Transportation in 49 CFR 195.2.

tive Density) of Plastics by Displacement

1.2 The values stated in inch-pound units are to be regarded

D1000 Test Methods for Pressure-Sensitive Adhesive-

as standard. The values given in parentheses are mathematical

Coated Tapes Used for Electrical and Electronic Applica-

conversions to SI units that are provided for information only

tions

and are not considered standard.

D1598 Test Method for Time-to-Failure of Plastic Pipe

1.3 This standard does not purport to address all of the

Under Constant Internal Pressure

safety concerns, if any, associated with its use. It is the

D1599 Test Method for Resistance to Short-Time Hydraulic

responsibility of the user of this standard to establish appro-

Pressure of Plastic Pipe, Tubing, and Fittings

priate safety, health, and environmental practices and deter-

D1600 Terminology for Abbreviated Terms Relating to Plas-

mine the applicability of regulatory limitations prior to use.

tics

1.4 This international standard was developed in accor-

D1693 Test Method for Environmental Stress-Cracking of

dance with internationally recognized principles on standard-

Ethylene Plastics

ization established in the Decision on Principles for the

D2122 Test Method for Determining Dimensions of Ther-

Development of International Standards, Guides and Recom-

moplastic Pipe and Fittings

mendations issued by the World Trade Organization Technical

D2256/D2256M Test Method for Tensile Properties of Yarns

Barriers to Trade (TBT) Committee.

by the Single-Strand Method

D2513 Specification for Polyethylene (PE) Gas Pressure

Pipe, Tubing, and Fittings

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic

D2774 Practice for Underground Installation of Thermoplas-

Piping Systems and is the direct responsibility of Subcommittee F17.68 on Energy

tic Pressure Piping

Piping Systems.

D2837 Test Method for Obtaining Hydrostatic Design Basis

Current edition approved July 1, 2023. Published August 2023. Originally

approved in 2011. Last previous edition approved in 2017 as F2896–11(2017). DOI: for Thermoplastic Pipe Materials or Pressure Design Basis

10.1520/F2896–23.

2

The reinforced polyethylene composite pipe product described in this standard

3

is covered by patents. Interested parties are invited to submit information regarding For referenced ASTM standards, visit the ASTM website, www.astm.org, or

the identification of an alternative(s) to this patented item to the ASTM International contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Headquarters. Your comments will receive careful consideration at a meeting of the Standards volume information, refer to the standard’s Document Summary page on

responsible technical committee, which you may attend. the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Consho

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2896 − 11 (Reapproved 2017) F2896 − 23

Standard Specification for

Reinforced Polyethylene Composite Pipe For The Transport

1

Of Oil And Gas And Hazardous Liquids

This standard is issued under the fixed designation F2896; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification covers requirements and test methods for materials, dimensions, workmanship, and markings for on-site

manufactured multilayer reinforced polyethylene composite pipe. It covers nominal sizes 6 in. through 36 in. (150 mm through

2

915 mm). These multilayered reinforced polyethylene composite pipe products are assembled and installed in various lengths,

including long continuous lengths. These products are intended for the transport of crude oil, natural gas and hazardous liquids in

the rehabilitation of existing pipelines and for new pipelines.

NOTE 1—Hazardous liquids are those liquids defined by the U.S. Department of Transportation in 49 CFR 195.2.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

3

2.1 ASTM Standards:

A312/A312M Specification for Seamless, Welded, and Heavily Cold Worked Austenitic Stainless Steel Pipes

A333/A333M Specification for Seamless and Welded Steel Pipe for Low-Temperature Service and Other Applications with

Required Notch Toughness

A519 Specification for Seamless Carbon and Alloy Steel Mechanical Tubing

D624 Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers

D638 Test Method for Tensile Properties of Plastics

D792 Test Methods for Density and Specific Gravity (Relative Density) of Plastics by Displacement

1

This specification is under the jurisdiction of ASTM Committee F17 on Plastic Piping Systems and is the direct responsibility of Subcommittee F17.68 on Energy Piping

Systems.

Current edition approved Aug. 1, 2017July 1, 2023. Published September 2017August 2023. Originally approved in 2011. Last previous edition approved in 20112017

as F2896F2896–11(2017).–11. DOI: 10.1520/F2896–11R17.10.1520/F2896–23.

2

The reinforced polyethylene composite pipe product described in this standard is covered by patents. Interested parties are invited to submit information regarding the

identification of an alternative(s) to this patented item to the ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend.

3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2896 − 23

D1000 Test Methods for Pressure-Sensitive Adhesive-Coated Tapes Used for Electrical and Electronic Applications

D1598 Test Method for Time-to-Failure of Plastic Pipe Under Constant Internal Pressure

D1599 Test Method for Resistance to Short-Time Hydraulic Pressure of Plastic Pipe, Tubing, and Fittings

D1600 Terminology for Abbreviated Terms Relating to Plastics

D1693 Test Method for Environmental Stress-Cracking of Ethylene Plastics

D2122 Test Method for Determining Dimensions of Thermoplastic Pipe and Fittings

D2256/D2256M Test Method for Tensile Properties of Yarns by t

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.